Tofu Structure Engineering: The Science of Crisping

🔬 Advanced Tofu Guide: Built for curious cooks, food developers, and flavour nerds — this post goes deep.

What really makes tofu crisp?

Not just heat, but a hidden dance of structure, moisture, and transformation.

This science-backed deep dive reveals the textures, temperatures, and techniques that turn humble tofu into golden-crisp perfection. Whether you’re a curious cook, a culinary developer, or a flavour-obsessed chef, this is your invitation to explore the precision science behind one of plant-based cooking’s most satisfying textures.

We’ll go beyond recipes to uncover the physics, protein networks, and crisping chemistry that empower you to engineer tofu, not just cook it.

I. Thermal Chemistry and Browning: Overcoming Water’s Thermal Barrier

Tofu crisping begins with one fundamental problem: water. Surface moisture keeps tofu temperatures stuck at ~100°C — the boiling point of water — which prevents browning reactions from taking hold. Once dry, however, the surface can exceed 140°C, the activation threshold for the Maillard reaction.

Key reactions by temperature:

Maillard Reaction: Begins ~140–165°C (284–329°F), involving amino acids and reducing sugars, generating roasted, umami-rich flavours.

Caramelisation: Sugar-only browning. Fructose starts ~110°C; glucose/sucrose near 160°C.

Pyrolysis: Begins >180°C — excessive charring leads to bitter, acrid off-notes.

🔥 pH Acceleration

Alkaline environments (e.g. a light baking soda dusting) speed up Maillard reactions by increasing the nucleophilicity of amino groups. Conversely, acidic environments inhibit browning and tighten protein structure (see Section VI).

II. Gel Matrix and Moisture Engineering: Structural Manipulation

Tofu is a water-rich gel composed of 7S (β-conglycinin) and 11S (glycinin) soy globulins. These proteins denature and set during coagulation, but their final structure remains malleable through moisture and thermal engineering.

Key Pre-Treatments:

Pressing (15–30 mins): Expels free water; firms the matrix.

Salt Blanching (2% salt, ~2 mins simmer): Osmotic dehydration + protein contraction = internal seasoning + tighter texture.

Freeze-Thaw-Press: Ice crystals rupture cell walls → spongier texture + better marinade absorption + chewy bite.

Denaturation Data:

7S: ~71–76°C

11S: ~86–93°C

Denaturation temp increases as tofu dehydrates — meaning firmer tofu requires higher heat for the same protein change.

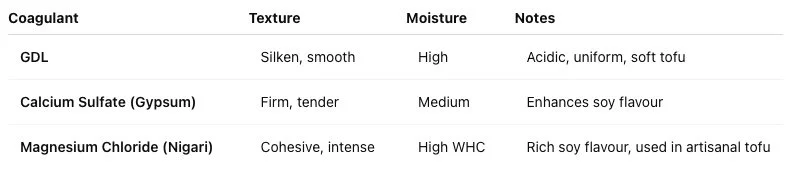

Coagulants Overview:

III. Starch Coating: Engineering the Perfect Crust

Gelatinisation:

Starch absorbs water and swells at 60–80°C, creating a sticky gel layer. As heat continues and water evaporates, amylose molecules form a rigid, glassy crust.

Retrogradation:

Retrogradation begins as food cools, especially in starches high in amylose. It doesn’t create crispness itself—that’s driven by surface dehydration and browning—but it stabilises and preserves crisp textures by reforming starch molecules into firmer, crystalline structures. This is helpful in fried or baked coatings. However, the same process also contributes to staling in items like bread, where amylopectin retrogradation gradually firms and dries the crumb.

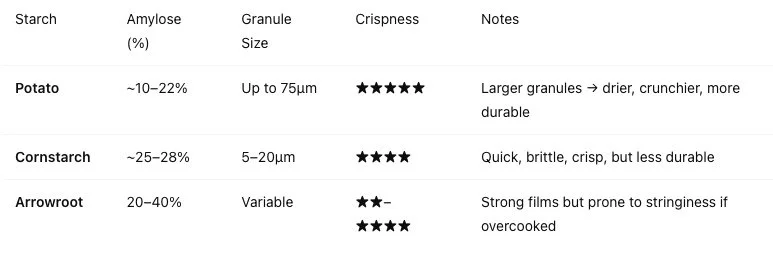

Corrected Crispness Rankings:

✅ Pro Tip: Dry dusting is superior to slurries. Thin, even layers = better dehydration + less sogginess.

IV. Heat Transfer: Choosing the Right Equipment

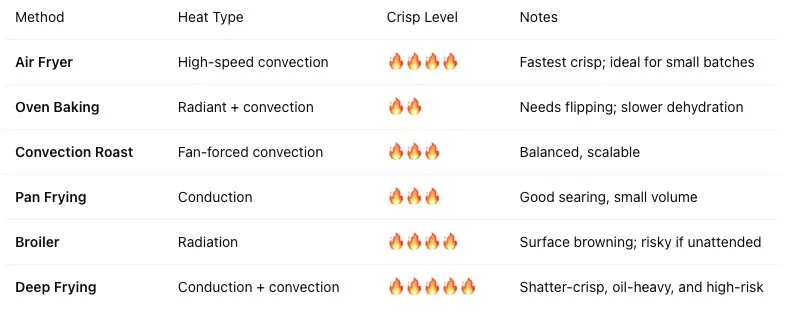

Tofu crisping succeeds when moisture is rapidly removed and the surface reaches 140–180°C. Each cooking method delivers heat differently:

Key Principle: Moisture removal is king. Without dry heat, tofu steams, not crisps.

V. Beyond Crisping: Advanced Tofu Texture Engineering

Fermented Tofu (Furu):

Traditional Chinese furu uses mould and brine to enzymatically break down tofu into a creamy, pungent, umami-rich condiment. Think: savoury cheese meets miso.

Sous-Vide (Exploratory):

Sous-vide (75–95°C) won’t form new gels (tofu is already set), but it can:

Gently soften the texture

Evenly infuse marinades under vacuum

Act as a pre-treatment before crisping

Transglutaminase (meat glue) can cross-link soy proteins and strengthen tofu’s structure. It’s not yet mainstream, but it’s scientifically validated for professional texturisation.

Hydrocolloids:

Used to stabilise, gel, or align proteins

E.g., carrageenan, gellan, xanthan, methyl cellulose

Enables fibrous or elastic textures, especially in meat analogues

pH Leverage:

Acid (vinegar/lemon): Tightens proteins → firmer texture, brighter taste

Alkaline (baking soda): Loosens proteins → softer texture, darker browning

This dynamic pH control is underused, but crucial for chefs aiming to modulate tofu’s finish with subtlety.

VI. Conclusion: From Cooking to Engineering

Tofu isn’t just a plant protein — it’s a modular culinary material. With the right understanding of heat, starch, moisture, pH, and protein structure, chefs can move beyond improvisation and into intentional tofu design.

Whether you’re aiming for shatter-crisp cubes, sponge-soft braises, or chewy umami blocks that absorb sauce like magic, every outcome can be engineered.

🧠 Next Level Tip: View tofu not as “complete,” but as programmable through technique, chemistry, and vision.

Let’s tofufy the future. 🌱